OUR CAPABILITIES

MILLING

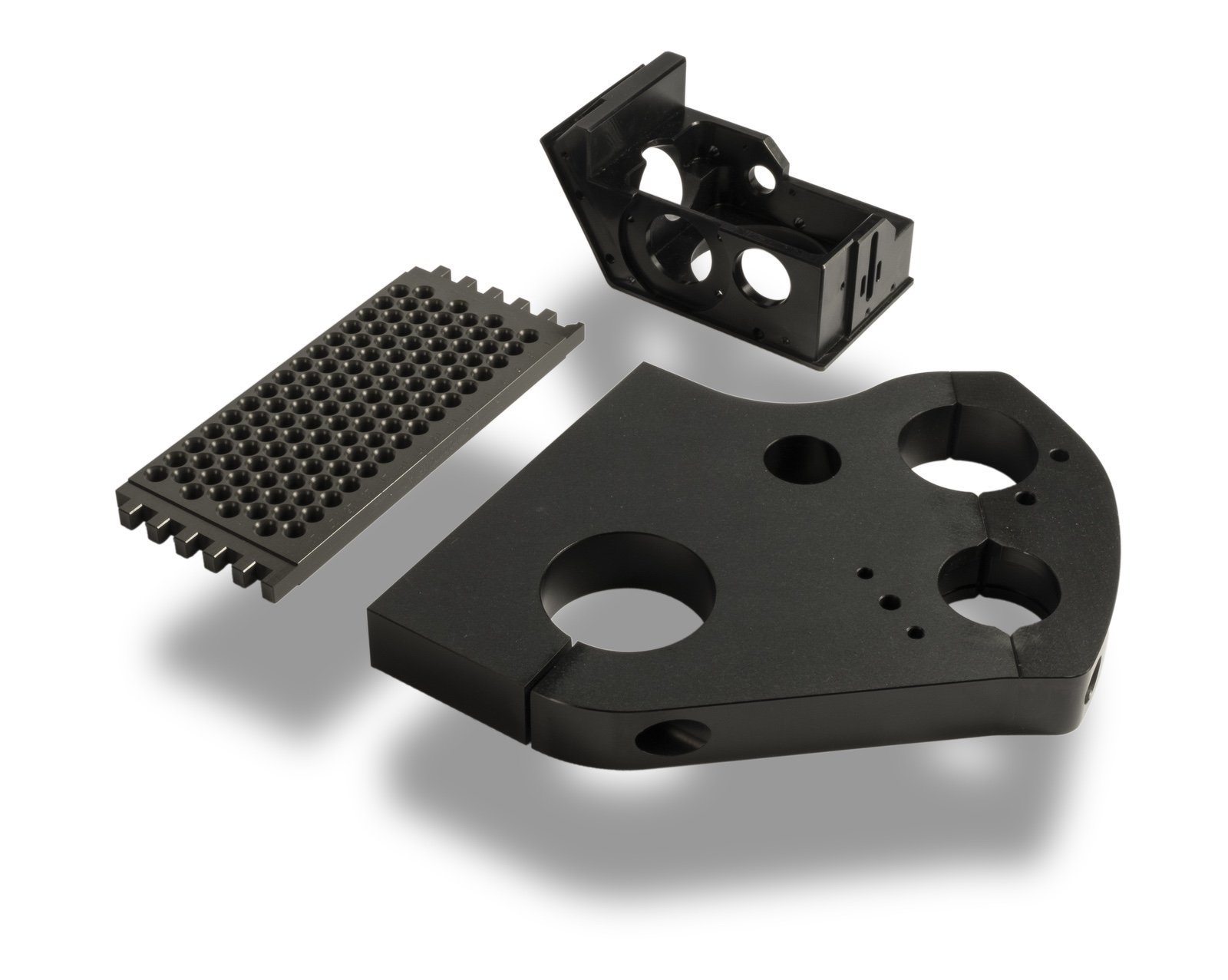

The milling department features 6 working areas: two 3-axis vertical machining centres with pallet changer 2 stations, one vertical machining centre with CNC tilting rotary table and 4th and 5th axis continuous machining, two 3-axis vertical machining centres and one vertical machining centre with 4th axis rotating table.

We run 4 and 5 axis machines with single and twin pallet variants allowing us to offer components from a few millimetres in size up to 1500 mm in length.

All machines are linked to our Metronomo 4.0 production management control software and to the Visi Vero CAD CAM system, allowing for easy data transfer, fast programming and a targeted control of every single processing phase.

TURNING

The turning department features 4 advanced CNC machines, including two multi-axis Takisawa machining centres for complex operations integrating milling and turning to remove the need for secondary steps. We can complete components in a single operation, reduce machining times & costs and improve accuracy. Compliance with the highest tolerances for the two Takisawa machines is guaranteed by an integrated cooling system both for the machines’ bases and for the emulsion fluids.

We run from ø 10 mm to ø 350 mm with twin spindle and double turret variants C and Y axis machining capability, with a bar loader of ø 80 mm max bar passage.

All machines are linked to our Metronomo 4.0 production management control software and the Visi Vero CAD CAM system, allowing for easy data transfer, fast programming and a targeted control of every single processing phase.

GRINDING

Our horizontal spindle grinder enables us to offer subcontract precision grinding. Maximum dimensions are 1300×650×500 mm. We also make Stainless Steel grinding and we provide circular grinding directly from our approved suppliers.

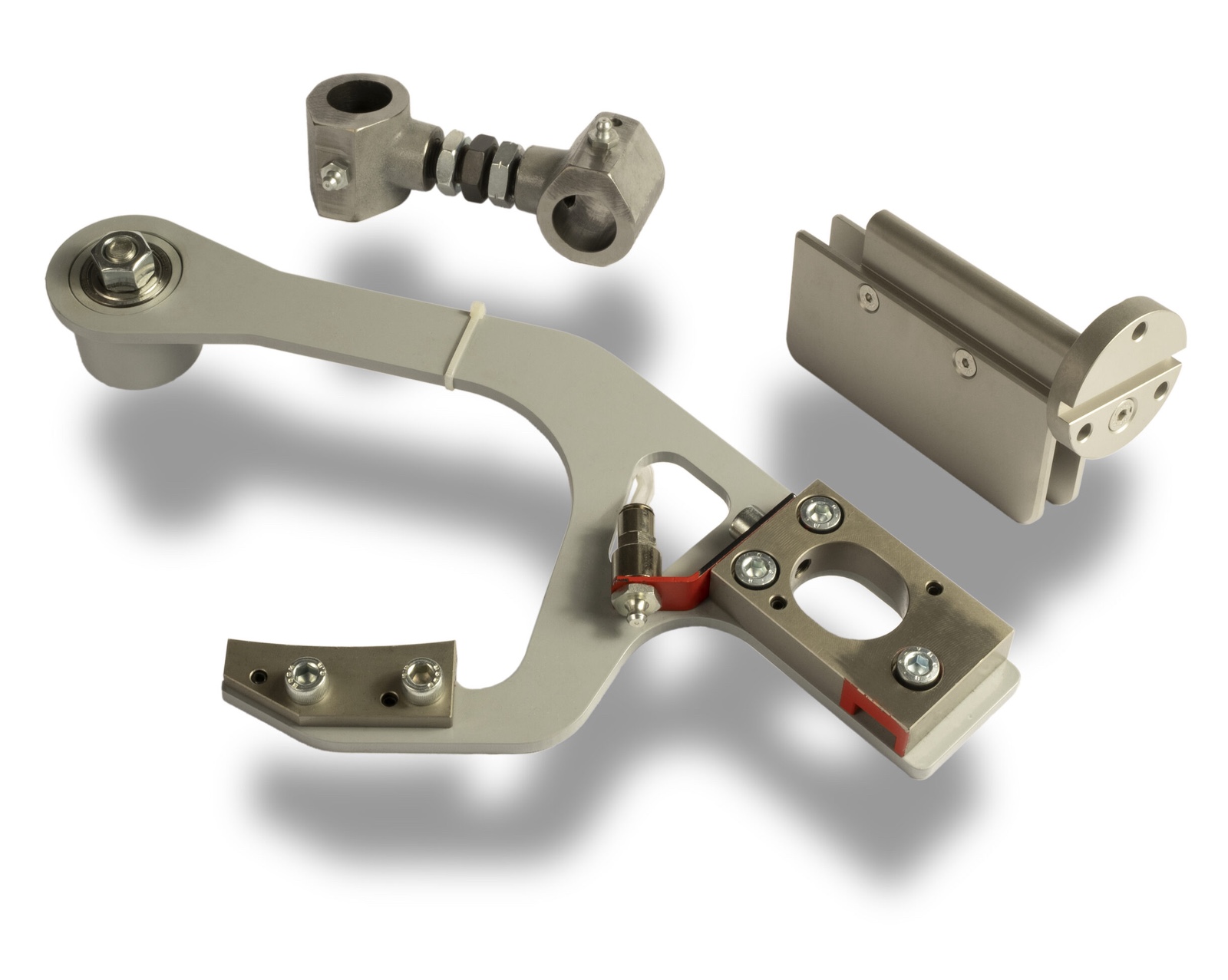

ASSEMBLY

Mancin has a functional unit assembly service, integrating components from several machining processes and providing its customers with complete products. This solution means customers can entrust a single supplier for all the machining and production processes.

At Mancin we care about quality, for this reason we ensure that raw materials, manufactured components, subcontract services and treatments correspond to customers’ specifications. We provide full standard and bespoke documentation for materials and treatments traceability.

MAIN MATERIALS

Stainless Steel, Steel, Iron, Cast Iron, Titanium, Brass, Bronze, Aluminium alloys, Magnesium, Plastic materials.

MAIN TREATMENTS & FINISHES

nickeling, hardening, tempering, annealing, carburizing, cementation, burnishing, anodizing, tumbling, sandblasting, paint finishes.

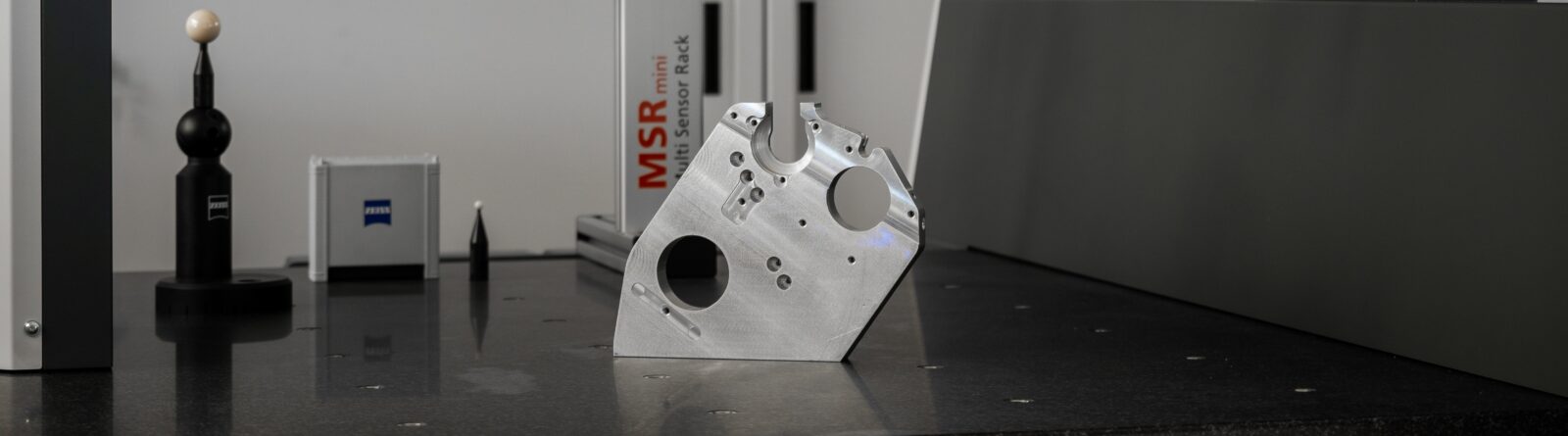

METROLOGY DEPARTMENT

Our staff working in the control & metrology department monitors and checks the entire production process and provides free specific test-reports for machined parts.

Our machines