TECHNOLOGIES

CAD/CAM 3D SOFTWARE

Our company has invested in the latest 5-axis CAD/CAM programming systems for milling and lathing to carefully quote your components, provide precise lead times, and machine the most demanding geometries.

We also have a production management software to manage the production cycle starting from price quotation to the final product, in a precise and reliable way. The software interfaces directly with our machines, measuring and detecting their production data in real time, thus providing updated and always reliable information 24 hours a day. Our staff is at your disposal also for technical advice and design.

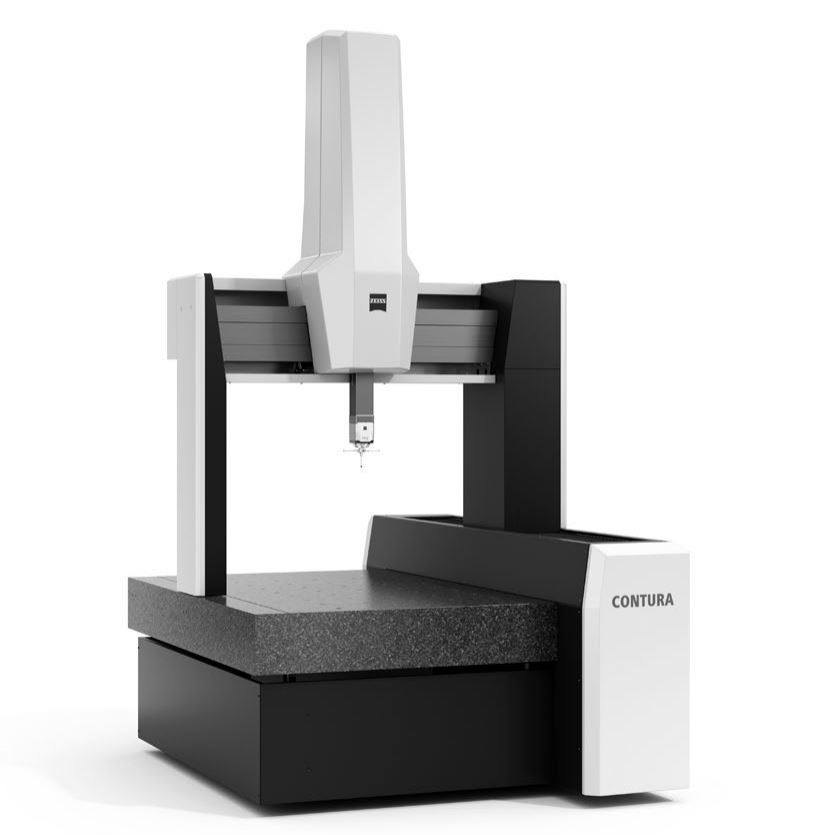

QUALITY CONTROL

Our company has a control & metrology air-conditioned room where we use one automatic 3D measuring machine “ZEISS” Contura with RDS sensor – travel 700x1000x600, one manual 3D measuring machine “DEA” with TF8 probe – travel 710x510x330 for control during the machining process and the final inspections, and a TESA Visio 200 GL – travel 200×100 vision machine for precise optical measuring. Moreover, each workstation is equipped with dimensional control instruments to accurately check every step in the production.

ISO 9001:2015 Certification

Our company has obtained the UNI EN ISO 9001:2015 certification in 2008 and has been able to establish itself as a leader in the production of integrated components for the most complex industrial productions.

ACHIEVABLE TOLERANCES

We typically machine components to +/-50 micron tolerances but can also fulfill tolerances as tight as 10 microns.

ELIMINATE EXTRA OPERATIONS

With our technologies we can increase productivity, reducing costs producing multiple precision machined parts simultaneously.

STOCKING YOUR PARTS

We can hold stock for JIT (Just-In-Time) or pre-planned call-off to reduce your inventory, improve cash flow and create valuable space at your site.

PACKAGED, LABELLED & READY TO SELL

To save you the hassles of having parts finished, we can offer you a complete service from manufacturing, assembly, packaging, logistics up to final shipment.